Understanding your tractor's ignition system wiring is crucial for maintaining farm equipment, minimizing downtime, and promoting sustainable agricultural practices. A broken-down tractor directly impacts productivity, wastes fuel, and potentially leads to crop losses. This guide provides step-by-step instructions to help you understand, troubleshoot, and perform basic repairs on your tractor's ignition system.

Safety First: Protecting Yourself

Before you begin any work on your tractor's electrical system, always disconnect the negative (-) terminal of the battery. This crucial safety precaution prevents electrical shocks and potential harm. Never compromise on safety.

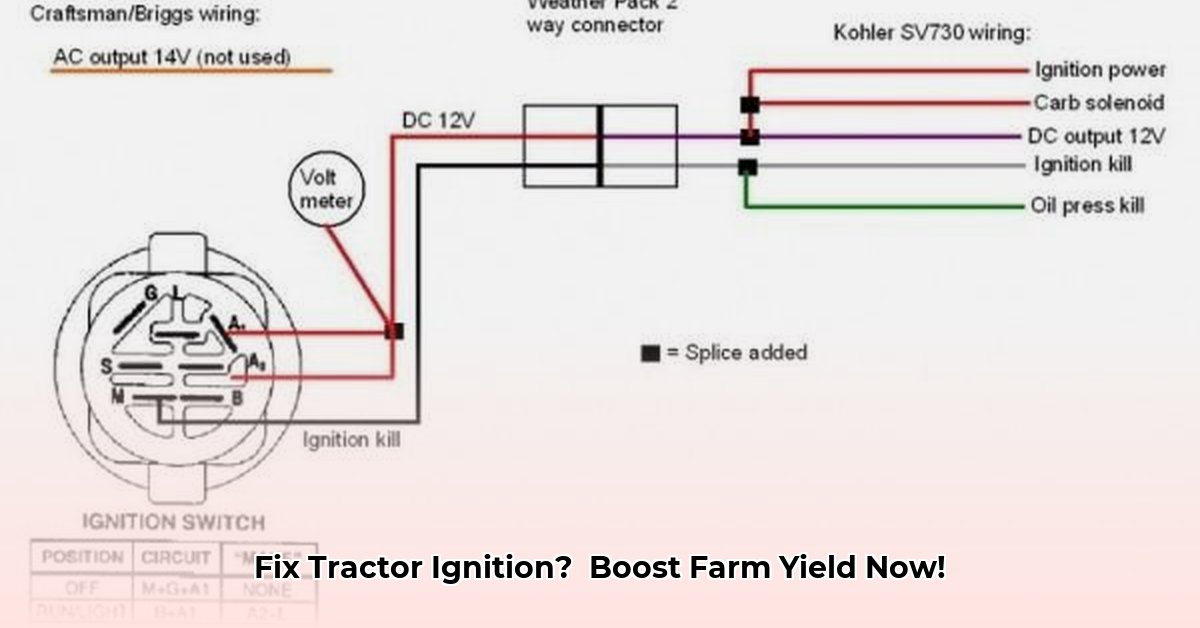

Deciphering the Wiring Diagram: Your Tractor's Electrical Blueprint

Your tractor's wiring diagram may seem daunting, but it's simply a visual representation of the electrical pathways within your machine. This diagram acts as a roadmap, guiding you through the connections between various components. Different lines represent wires (often color-coded); symbols represent parts like the ignition switch, starter motor, battery, and fuses. Your owner's manual provides a key explaining these symbols.

Here's a simplified example of common symbols:

| Symbol | Component | Description |

|---|---|---|

| --- | Wire | A single electrical wire. |

| ○ | Connector | Where wires are joined. |

| □ | Ignition Switch | Controls power to the ignition system. |

| ≡ | Starter Motor | Cranks the engine to start it. |

| + | Battery Positive (+) | Positive terminal of the battery. |

| - | Battery Negative (-) | Negative terminal of the battery. |

| ∧ | Fuse | Protects against overcurrent. |

| ~ | Ground | Connection to the chassis (earth) to complete a circuit. |

Troubleshooting Common Ignition Problems: Solving the Puzzle

When your tractor won't start, systematic troubleshooting is key. Use your wiring diagram to guide you:

1. Visual Inspection: Carefully examine all wiring around the ignition system for broken or frayed wires, loose connections, or corrosion. A simple visual check often reveals the problem.

2. Battery Voltage Test: Use a multimeter (a device that measures voltage and resistance) to check the battery voltage. It should read approximately 12 volts. A low voltage indicates a weak battery. Did you know that a weak battery accounts for over 50% of no-start issues in tractors?

3. Ignition Switch Continuity Test: The multimeter helps check the ignition switch circuit's continuity. The wiring diagram shows which wires to test.

4. Starter Motor Voltage Check: Trace the starter motor circuit according to the diagram. Test for voltage at the starter motor terminals while attempting to start the engine. No voltage points to a problem upstream.

5. Solenoid Check: The solenoid is a relay connecting the ignition switch to the starter motor. Test its continuity to confirm it's working correctly.

Basic Repairs: Simple Fixes for Common Issues

After identifying the problem, these simple repairs might be within your capabilities:

1. Repairing a Broken Wire: Carefully cut out the damaged section of wire and splice in a new piece of the same gauge, using appropriate connectors. Insulate the connection thoroughly with electrical tape.

2. Tightening Loose Connections: Firmly tighten any loose terminals or connectors. Clean corroded terminals with a wire brush and contact cleaner.

3. Replacing a Connector: If a connector is damaged, replace it with one matching the original specifications.

Important: For complex repairs or if you’re unsure, always consult a qualified mechanic. Improper electrical repairs can cause further damage.

Boosting Farm Efficiency: The Big Picture

Mastering your tractor's ignition system wiring diagram dramatically improves operational efficiency. By understanding these diagrams and performing basic maintenance, you reduce costly downtime and maximize your farm's output, contributing to sustainable and profitable agricultural practices. "Understanding your equipment’s electrical system is a significant step toward improving your farm's sustainability," says Dr. Anya Sharma, Agricultural Engineering Professor at Purdue University.

"Regular maintenance and proactive troubleshooting are essential for preventing costly breakdowns and maximizing productivity," added Dr. Sharma.

Remember to always refer to your tractor's owner's manual for detailed diagrams and specific instructions. Online forums and manufacturer websites provide additional resources.